How To Automate CNC Machines Without Breaking the Bank

By Laura Cowan

Laura K. Cowan is a tech, business, and wellness journalist and fantasy author whose work has focused on promoting sustainability initiatives and helping individuals find a sense of connection with the natural world.

This is a guest post from Jonathan Schlick, Manufacturing Manager of Techni Waterjet. The opinions and statements in this article are the sole responsibility of Mr. Schlick and do not necessarily reflect the opinions or positions of Techni Waterjet or Cronicle Press.

If you would like to write a guest post for Cronicle Press, please email the editor. We are looking for guest posts in tech industry thought leadership, entrepreneurship and startup culture, and book and media reviews of tech-related content.

Jonathan SchlickToday’s Techni Waterjet Manufacturing Manager, Jonathan Schlick, has over 20 years experience in the field of industrial machinery. After a 12-year career in laser machinery, he moved to waterjets where he’s grown his skills and knowledge of the technology through leading Techni’s Regional Service. Working around the globe for the metal, stone, glass, and automotive industries, Jonathan is an expert on modern cutting solutions and has developed a unique ability to discern pros and cons of the different machines available on the market.

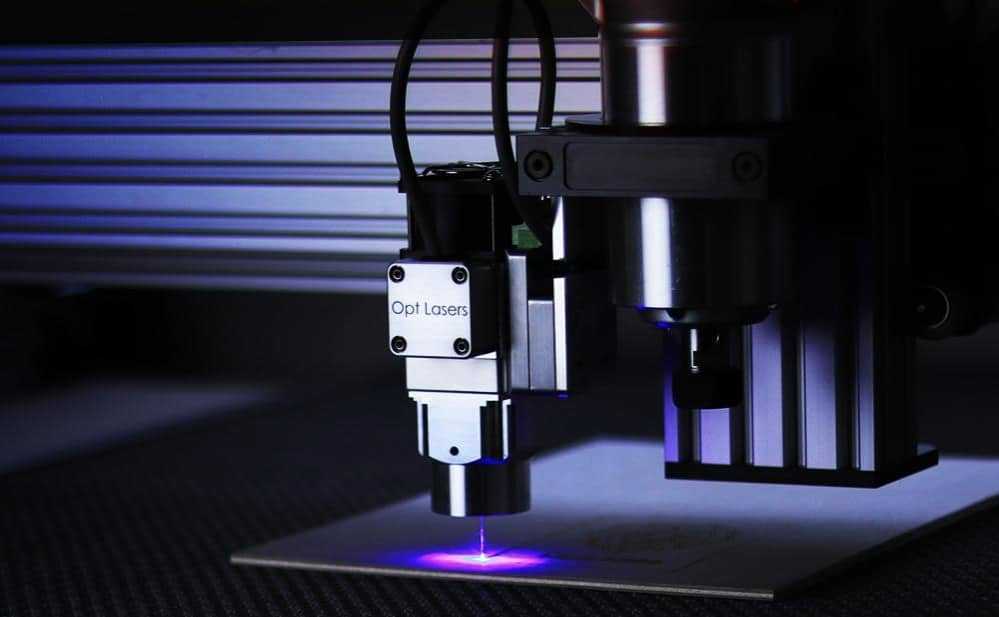

Photo courtesy Techni Waterjet

How Can a CNC Machine Be Automated Cost-Effectively?

The robotics and automation industry has grown exponentially over the past decade. The market for robotics technology in the world was worth $62.75 billion in the year that ended in 2019 and is predicted to grow to $189.36 billion by 2027. One of the critical elements that have contributed to the growth of the robotics industry is the integration of modern manufacturing techniques, such as CNC machining.

What is CNC Machining?

A computer numerical control (CNC) machine is a technology for manufacturing which relies on computer commands to translate and interpret 3D drawings into machined components. The high precision, accuracy, and other benefits make them among today’s most famous manufacturing technologies.

If you’re unsure how to automate your CNC machine, you’re not alone. Forbes has done a study that claimed that the average Fortune 500 company could save up to $4.7 million each year. In addition, EY recently published an article about Zurich, Switzerland, where industrialisation was already in place. These are examples of tangible results that can bring to companies worldwide.

This article will examine how businesses in the automation and robotics industries use CNC machines. We will also discuss how a CNC machine can be automated cost effectively over other manufacturing techniques in the robotics sector.

Photo courtesy Techni Waterjet

CNC Robotics Machining: The Overlap and Benefits

CNC machining and robotics frequently overlap. CNC machines’ actions depend on computers and control technologies (computer numeric control technology). Robots and automation sectors benefit from CNC processing.

CNC machines are precise and precise, with precision as close as 4 millimetres. Therefore, they are indispensable in robotics, with strict requirements regarding the precision and accuracy of manufactured parts. CNC machining offers short time frames, allowing the creation of the last piece in just a few hours, while conventional manufacturing can require weeks (sometimes months) to finish.

What Makes CNC Machine Automation Cost-Effective

Most CNC technologies are developed as program machines such as CNC waterjet and permit them to perform various tasks following specifications. But there are other specific reasons CNC automation is employed in modern machining. These are:

Reason #1: Speed

Since CNC machines can be used for carrying out multiple tasks in the production process, they significantly boost efficiency. They cut down on the time required to complete each production batch. CNC machines can also conduct specific studies faster and more efficiently than the standard workforce.

Reason #2: Capacity

CNC machines produce higher production quantities continuously and in a similar way. Leaving aside machine mistakes or malfunctions in programming, the technology can eliminate mistakes made by the user. When the machines run longer and can handle more work, the company’s production capacity is also increased.

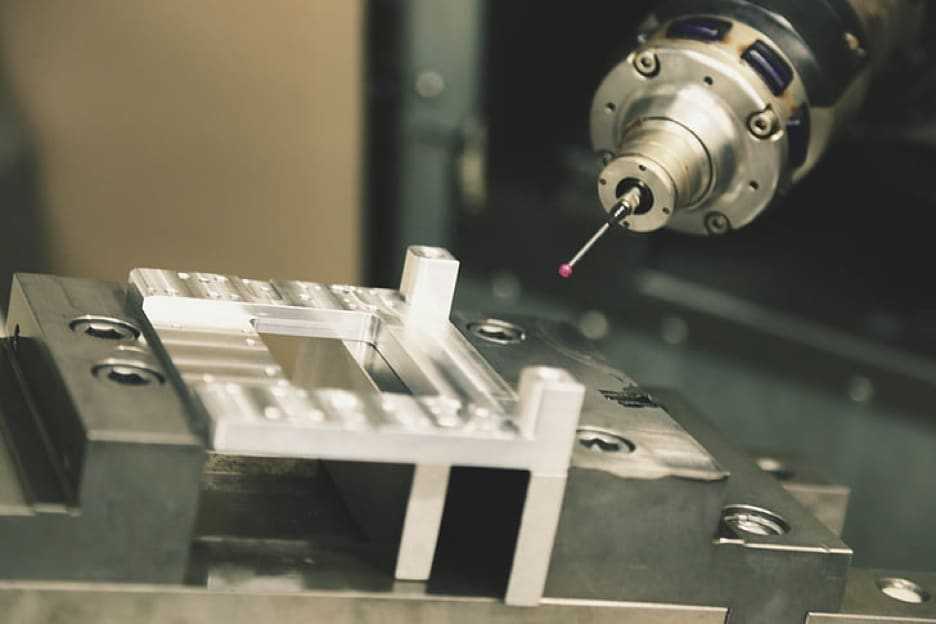

Photo courtesy Techni Waterjet

Reason #3: Efficiency

One of the most appealing aspects of CNC automation for manufacturing is that it can perform high-precision. It means your business can cut down on waste production from each workpiece. It also lowers the overall cost of production for your business.

CNC machines do not require direct human intervention; You can use them all day. It means that you can work without being concerned about the product’s performance.

Reason #4: Consistency

Utilising a CNC machine implies you can make the same product and complete the same tasks precisely, regardless of how many instances you repeat the process. Manufacturers must also consider that these machines can operate 24/7, but they require periodic maintenance and repairs to last for a long time.

Reason #5: Safety

The latest technology machines function independently. The person responsible for the operation has to have programmed the program to run the machine. The device will work effectively and safely without the operator’s attention.

Therefore most manufacturing companies that work with harmful or corrosive substances and high temperatures employ CNC automation. This is also a safer method for working in hazardous types of work.

Reason #6: Simplicity

Single operators can easily oversee and manage several machines simultaneously in normal circumstances. It means the company saves money from labour costs.

However, the CNC can execute the programs according to the operator's data with production machines. The user must be cautious when entering data to avoid incorrect results.

Photo courtesy Techni Waterjet

Automated Key Parts Made With CNC Machining

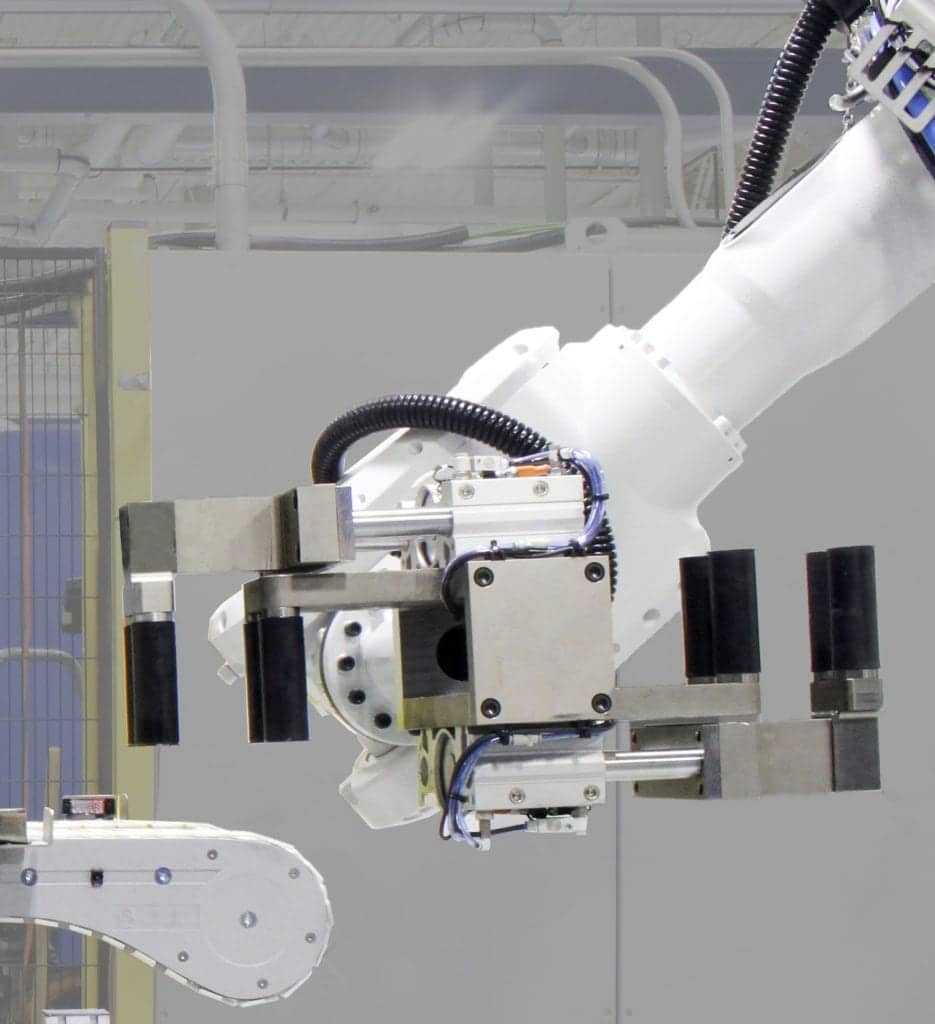

Robotic Arm

Robotic arms form an integral element of equipment that functions as a human hand and helps move or perform actions on objects. Though initially designed to automate die casting, robot arms can be found in various devices, including CNC machines and material handling equipment and pick-and-place machines, just to mention some.

Since manufacturers mostly employ robotic arms to move things, their components are composed of high-strength metals such as aluminium, steel, and some plastics. CNC machines are compatible with various materials, perfect for machining these components.

The subtractive CNC machines mean you can create plastic parts without compromising the component’s structural integrity (this isn’t the case with additive manufacturing techniques, such as 3D printing).

End Effectors

End effectors are an instrument attached to the robotic arm, allowing it to be in contact with the objects and perform various tasks. End effectors can vary in design and function, such as grabbers, grippers and suction pumps. They have the same thing in common: they are typically made using CNC machines.

Designers of products design “end effectors” to have different surface roughnesses based on the purpose. For instance, CNC machines can design parts with an approximate surface roughness of Ra 0.8mm, perfect for making end effectors with outstanding surface finishes.

Photo courtesy Techni Waterjet

Custom Jigs and Fixtures

Custom-designed jigs and fixtures play an essential part in all robots: they help keep the pieces in position (or identify factors within space) while robots work on them. As their names suggest, the term “custom jigs” and fixtures are made to order, and there isn’t any manufacturing technology that’s as affordable as CNC manufacturing for customised components.

Sensors and Controllers

PCBs have printed circuit boards (PCBs) are essential components in the controllers and sensors, which comprise a variety of robotics and automation tools. While chemical etching is the main stage in PCB production, CNC machining is helping to solve some issues with this procedure.

Chemical etching uses ferritic chlorine, a poisonous substance which causes skin irritation. Causes iron accumulation in the body and demands massive waste disposal procedures. CNC is currently being utilised as a substitute for chemical etching.

Final Words

Regarding the new machines, the digitization of manufacturing is an issue of significant fascination. All of it will be smart, and the milling device will be the primary one accountable for the re-ordering of blanks.

Extensive production facilities are making progress in this direction. But the solution is usually not profitable or cost-effective, particularly for small production firms.

If this is the case for you, Techni Waterjet would be glad to assist you in developing the most cost-effective method yourself; ensuring that you can automate your device with a quick ROI and possibly enjoy some fun.

advanced manufacturing, automate cnc machines, automation, cnc machine automation