announcements, medical tech, university of michigan

Durable Antimicrobial Coating Kills Drug-Resistant Bacteria in Minutes

By Laura Cowan

Laura K. Cowan is a tech, business, and wellness journalist and fantasy author whose work has focused on promoting sustainability initiatives and helping individuals find a sense of connection with the natural world.

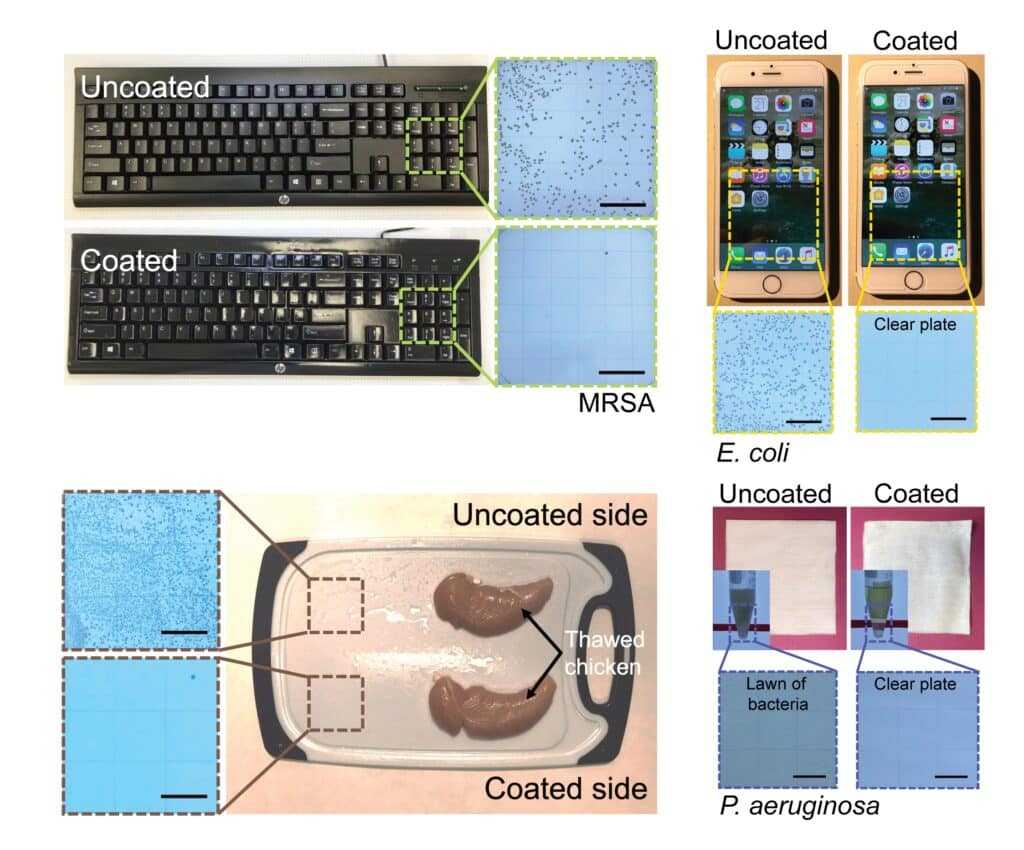

Photo courtesy the University of Michigan. The antimicrobial coating is clear, even when applied in a thick layer to surfaces.

News out of the University of Michigan today says that a new durable antimicrobial coating used on hard surfaces can kill the bacteria that causes COVID-19 in minutes. This coating could be used for other bacteria and viruses as well: A team of University of Michigan engineers and immunologists have developed the material, which proved deadly to SARS-CoV-2, E. coli, MRSA (the drug-resistant bacteria found in operating rooms and hospitals) and a variety of other pathogens.

What is unique about this durable coating is that it killed 99.9% of microbes even after months of repeated cleaning and abrasion from use of high-traffic use such as keyboards, cell phone screens and even raw chicken-covered cutting boards. This surface might be a game changer for public spaces like hospitals and airports where pathogens spread.

Anish Tuteja, professor of material science and engineering at the University of Michigan and co-corresponding author of the paper just published in Matter on this new material, says, "We’ve never had a good way to keep constantly-touched surfaces like airport touch screens clean. Disinfectant cleaners can kill germs in only a minute or two but they dissipate quickly and leave surfaces vulnerable to reinfection. We do have long-lasting antibacterial surfaces based on metals like copper and zinc, but they take hours to kill bacteria. This coating offers the best of both worlds."

The coating is clear and can be brushed or sprayed on to surfaces. It gets its durability and potency by combining antimicrobial molecules derived from tea tree oil and cinnamon oil, both known for many years as natural antibacterial and antiviral agents, with durable polyurethane, a tough flexible sealer often used to protect hardwood floors.

"The antimicrobials we tested are classified as 'generally regarded as safe' by the FDA, and some have even been approved as food additives," Tuteja said. "Polyurethane is a safe and very commonly used coating. But we did do toxicity testing just to be sure, and we found that our particular combination of ingredients is even safer than many of today’s antimicrobials."

Photo courtesy the University of Michigan. This image shows the difference in pathogen load of coated versus uncoated surfaces.

The study's durability test indicates that the coating could kill germs for six months or longer before the oils evaporate. But even then, Tuteja says, the coating could be recharged by wiping it with fresh oil. The surface would reabsorb the oil, and activate it for another six months. This would save an enormous amount of time and cost cleaning surfaces, and protect people against pathogens.

The technology has been licensed to Hygratek, a company Tuteja founded with help from U-M Innovation Partnerships (formerly the Office of TechTransfer).

Associate professor of materials science and engineering and biomedical engineering at the University of Michigan Geeta Mehta, a co-corresponding author; and materials science and engineering PhD students Abhishek Dhyani and Taylor Repetto, co-first authors—found a possible solution to extend the use of the material through cross-linking, a process that uses heating to link materials together at the molecular level. Smaller oil molecules easily combine with the cross-linking polymer molecules, forming a stable matrix. The oil molecules need to penetrate germs' cell walls, which they can't do while tethered to the matrix, so the researchers found a solution in partially cross-linking the materials to keep some oil molecules free to kill pathogens. Tuteja says that this keeps some oil in reserve so the coating is effective for longer: "The free oil tends to stay with the oil that’s cross-linked into the matrix, helping the coating last longer."

The formula allows the product to be used for specific applications using different active ingredients. This means the technology could be used with different antimicrobial agents to kill specific germs. The University of Michigan has applied for a patent for the technology, which aims to create a "library" of possible coatings used for different purposes.

If you would like to read the study, you can find it here: Surfaces with instant and persistent antimicrobial efficacy against bacteria

and SARS-CoV-2 (DOI: 10.1016/j.matt.2022.08.018)

covid 19, drug resistant bacteria, durable antimicrobial coating, medical tech, mrsa, university of michigan